Mesh Masters can supply mesh produced out of aluminium.

Aluminium is produced with raw material that is extracted from bauxite. To produce aluminium out of bauxite, a lot of energy is required. This is why the majority of the offered aluminium consist out of recycled material.

To recycle aluminium, only 5% of the energy is used compared to extract it from bauxite.

Aluminium is a material with relatively low weight, in general, high tensile strength and is a good conductor.

Just as stainless steel, there are different alloys available for aluminium. Each with their own characteristics.

These differences appear in weldability, how it can be deformed and corrosion-resistance.

Aluminium is often applied because of the combination of relatively low weight and high strength.

Like stainless steel alloys, aluminium alloys are also classified into groups. These groups are divided according to the NEN-EN 573 standard.

Of course, not all alloys are suitable for weaving, knitting or perforated media, but in the overview below, some of these groups are explained.

1000-series

The aluminium that includes this series, is unalloyed and contains at least 99,00% aluminium.

This material is very suitable for welding, has a high corrosion resistance and is good to deform.

Furthermore, the alloys in this series have a high electrical conductivity.

Aluminium from the 1000-series can be found in the chemical industry, food industry and can be used as high voltage- or welding cable.

2000-series

In the 2000-series there is added copper to the aluminium. In general, together with magnesium. This alloy does require a heat treatment to achieve the best properties.

Because of this composition, together with the treatments, this alloy has got a very high mechanical strength. On the other hand, this alloy is difficult to weld. Furthermore, the ability to deform this alloy and the corrosion resistance is lower than the 1000-series.

Material with this alloy is good to use for parts that require a good strength up to 150°C. Furthermore, constructions where a high strength/weight ratio is required, aluminium from the 2000-series are very suitable.

3000-series

Aluminium that is categorized in the 3000-series contains manganese.

Most of the alloys in this series are not suitable for hardening but are about 20% higher than aluminium from the 1000-series.

Although the strength of the alloys in the 3000-series is about 20% higher than the 1000-series, the strength is low.

Against this, this alloy is very suitable for welding, good to deform and is well resistant to corrosion.

Examples of the use of this alloy are heat-exchangers, storage tanks, corrugated sheets or cans.

4000-series

Silicon is the main additive for aluminium in this series. There can be added up to 12% of this material. Because of this, the melting point is lower without the alloy is becoming brittle.

This is why this alloy is often applied as a soldering material or welding additive.

Most of the 4000-series aren’t able to harden.

When there is added enough silicon, the material can get an anthracite colour when anodize.

This is why this alloy can be found in architecture.

Aluminium from the 4000-series has got an average strength and tensile. The corrosion resistance is good and suitable for welding.

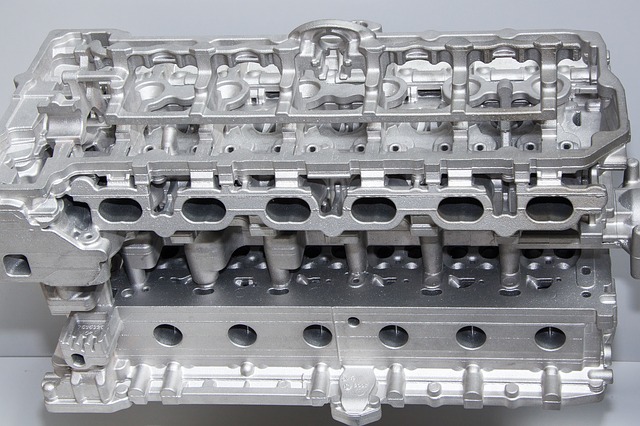

Material from the 4000-series is generally used as a casted alloy and is used, among other things, for cylinder heads, propeller blades and engines.

5000-series

In the 5000-series there is magnesium added as the most important element. This can be combined together with manganese.

Alloys in this series are good resistant against corrosion in maritime environments. Because of this, this alloy is often applied in shipping. Furthermore, this alloy can be found in bodywork construction and architecture.

The strength is average to high, has got tolerable deformability, a good corrosion resistance and a good weldability.

6000-series

Aluminium in this series can be hardened. This is because this alloy contains silicon and magnesium.

Due to the ratio of these elements in this alloy, Mg2Si can be formed.

When this alloy is solution annealed treated, it can be deformed well thermally (T4). After hardening, this alloy has got much more strength.

The 6000-series aluminium are suitable for welding, is good resistant against corrosion and can be machined well. Furthermore, this alloy has got a good electrical conductivity.

This alloy can be found in bike frames, electrical conductors, trains and bridges.

7000-series

In this category, the element zinc is added. When there is also added a small amount of magnesium, it is possible to harden this alloy.

Besides these elements, there are also added copper and chrome. When an alloy has got a high strength, it is generally more sensitive for stress corrosion.

That is why this alloy is mainly used in the obsolete condition.

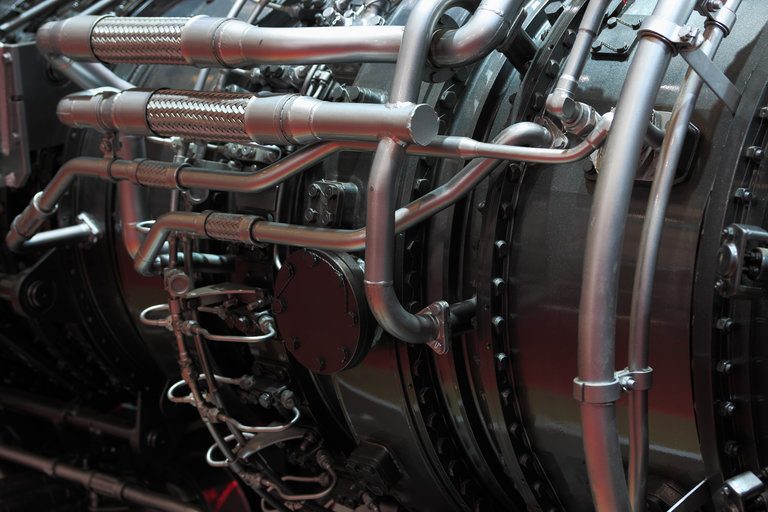

Alloys in this series can be found in aviation and mobile equipment.

8000-series

Aluminium in the 8000-series is an alloy that isn’t applied often. This series is developed to create an even lighter alloy.

It has got a 10% higher E-modulus and that is why it isn’t easy to deform.

Alloys from this series can be found in aerospace or aviation.