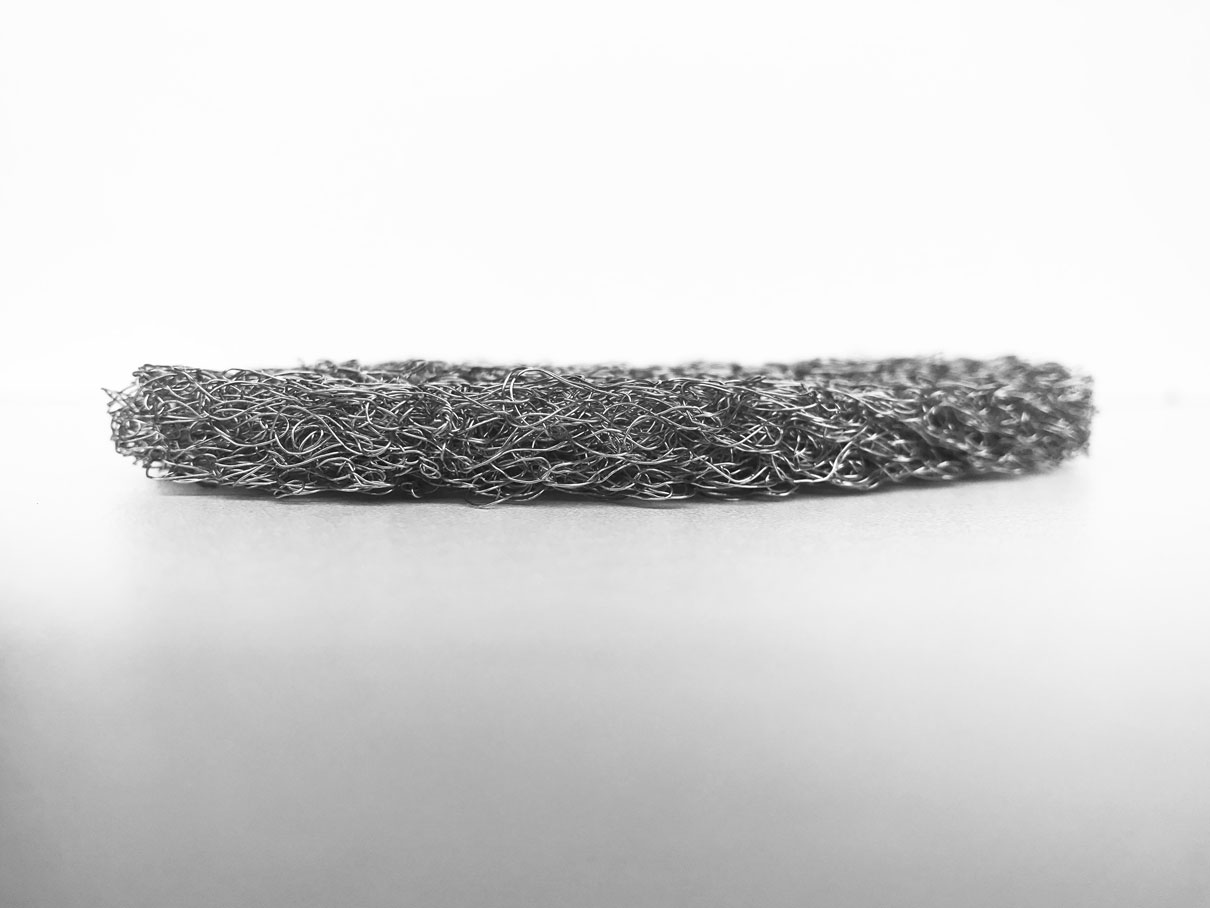

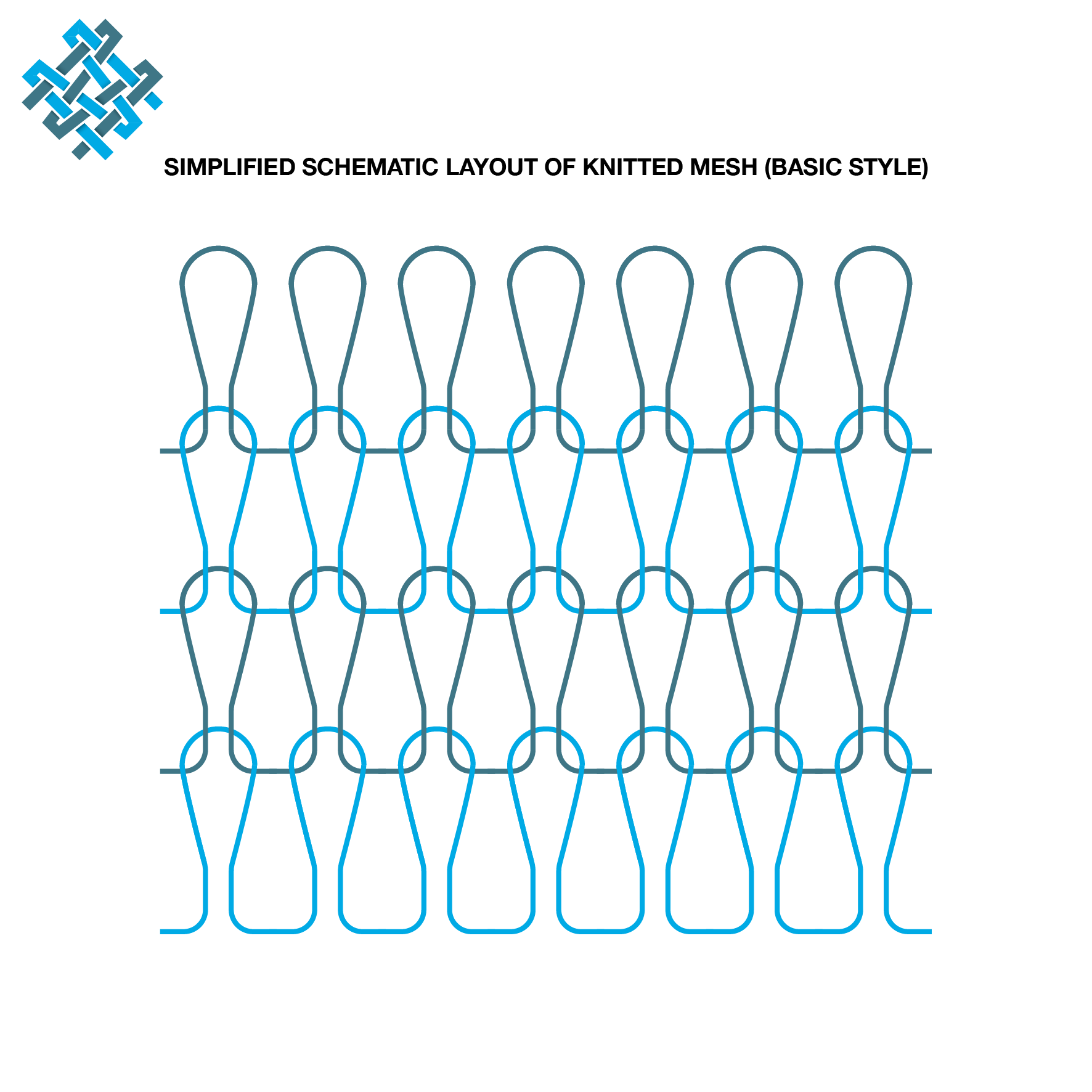

Knitted fabric owes its characteristic structure to wires that are mixed in a waveform. Because of the material’s great stretchability, it is suitable for being used in various forms and for many applications.

Of course, the processing of the knit determines for which application it can be used.

Processes that can be done with a knitted material are calandering or it can be crinkled.

Furthermore, knitted material can be pressed into a filter in a mould. For example to create a smaller open area.

Knitted mesh

Knitted mesh can be made in almost any material that is available in wire form.

Materials that Mesh Masters can offer include stainless steel (AISI 304, 316(L), 904(L), etc.), copper, aluminium, etc.

Other possibilities are to knit stainless steel combined with a plastic such as PP.

We are able to supply our round-knit on a maximum flat width of 700mm. with wire diameters available between 0,10 and 0,60mm.

In addition to knit with round wire, it is no problem to knit with flat wires.

Our knitted mesh is produced in flat or crinkled condition and is used for filtration purposes, separation applications, protection, RFI-shielding or reinforcement.

Knitted filters

Mesh Masters supplies knits that are shaped into filters for various applications.

These filters, also knowcalled demisters or coalescers, are used to separate liquids from gasses in, for example, the petrochemical industry.

Our knitted filters are generally produced in AISI 304(L) or AISI 316(L) but are available in all earlier mentioned alloys and, if required, produced with or without supporting grids.

We produce these filters completely according to our customer’s specifications to meet all required process requirements.

Our knitted mesh filters can mainly be found in filtration and separation applications.