Punched plate

Openings in plate material can be can be applied in different ways and are used for many applications and in various industries.

For instance, sieving, filtering, protecting or controlling an air flow or liquid flow.

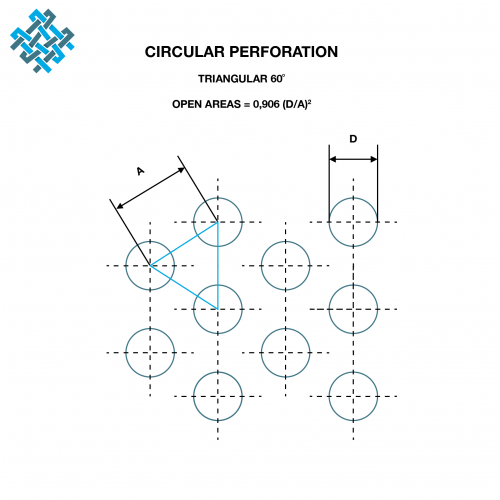

When a perforation is applied, the following parameters need to be observed:

In this image, A is the distance from the heart to heart between the holes, better known as ‘pitch’.

D implicates the size of the hole, in other words, the diameter (Ø).

Furthermore, the angle of the position of the holes is of importance. This can be straight, triangular or staggered.

Punched plate

The most common way of perforating is by punching.

Mesh Masters is able to supply your plates exactly according to your requirements.

This can be with blank areas, different angles, square perforation or slots.

Our plates are available on a thickness from 0,3 up to 20 mm. for steel. For stainless steel, this is 15mm.

Standard plate size is 2000 x 1000mm.

However, we have possibilities to supply plates to a maximum size of 6000 x 2000mm.

After punching, plates will be straightened and degreased to remove residues that are used during the process.

Available alloys are steel, stainless steel, Inconel™, Incoloy™, Monel™, Duplex™, titanium, copper, and brass for example.