Woven wire mesh

Woven wire mesh is used for numerous purposes and in very diverse industries. Applications can be filtering, laminating, sieving, reinforcing or decorating.

Depending on the use, we are able to supply your mesh completely according to your demands. Important parameters for producing mesh are material, wire diameter, mesh opening and weaving pattern.

Available in alloys like steel, galvanised steel, stainless steel alloys for example Aisi 304, Aisi 316, Aisi 321 and Aisi 430 or copper. Furthermore, we can provide materials like Inconel™, Incoloy™ and Hastelloy™ through our delivery program.

With each weaving pattern, mesh acquires its own specific properties. We can achieve an opening of just 5 micron or several centimetres.

Weaving patterns

Mesh Masters can supply mesh for any purpose.

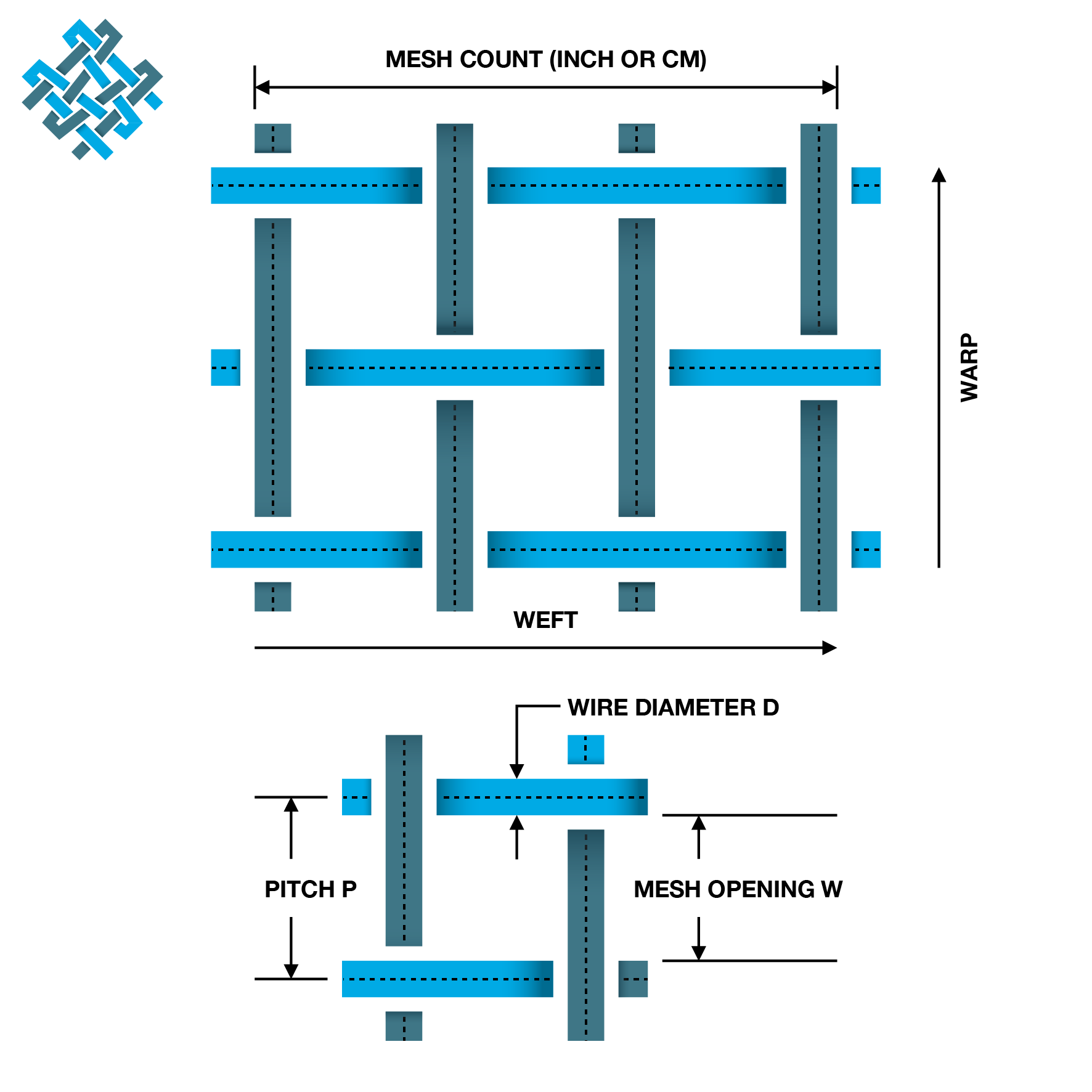

In the image below, the parameters of woven wire mesh are explained.

- Mesh count is the number of meshes counted in a row in a unit of length. Usually, this is mentioned per inch;

- Mesh opening (w) is the distance between two wires in warp or weft direction;

- Wire diameter (d) is the diameter of the wire before weaving. Pitch (p) is the distance between the center of two wires in warp or weft direction;

- Warp is the wire that runs parallel in the length direction of the roll;

- Weft is the wire that runs in parallel with the width of the roll. This wire is perpendicularly braided of the warp

Depending on the purpose, the weaving pattern will be determined for the choice of mesh.

A weaving pattern acquires properties due to the way the warp and weft are connected.

Frequently used weaving patterns are described below.

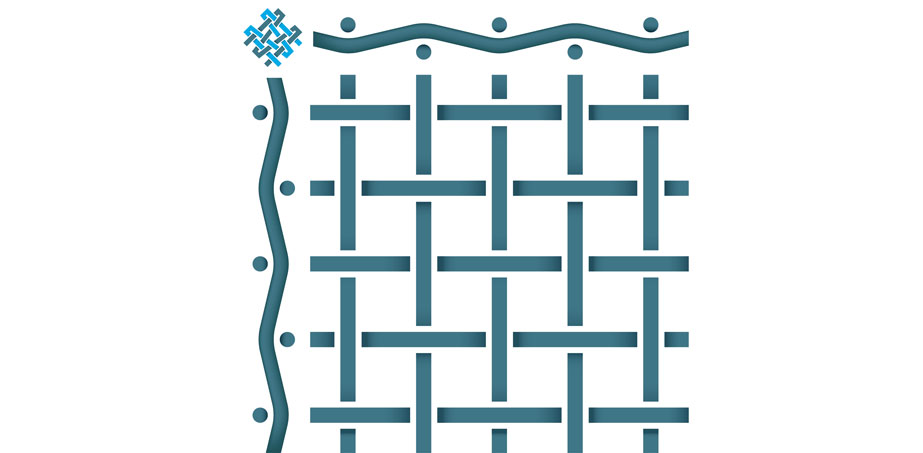

Plain weave

The most common way of weaving. In this weaving pattern, the wires are alternately woven over each other. Usually, the wire diameters from warp and weft are similar.

The smallest mesh opening we supply using a plain weave is 25μm.

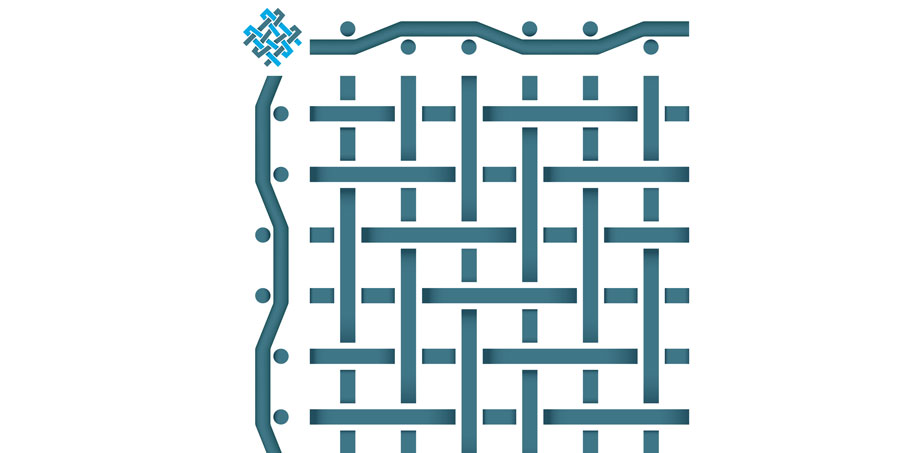

Twilled weave

With this weaving pattern, the wires are woven per two wires over and under the next adjacent pair of wires.This way, a diagonal pattern appears which is characteristic for this type of weaving.Twilled weave offers the possibility to use a thicker wire without deforming during weaving. This way, the mesh is more stabilized.

The smallest opening with a twilled weave we are able to supply is 20μm

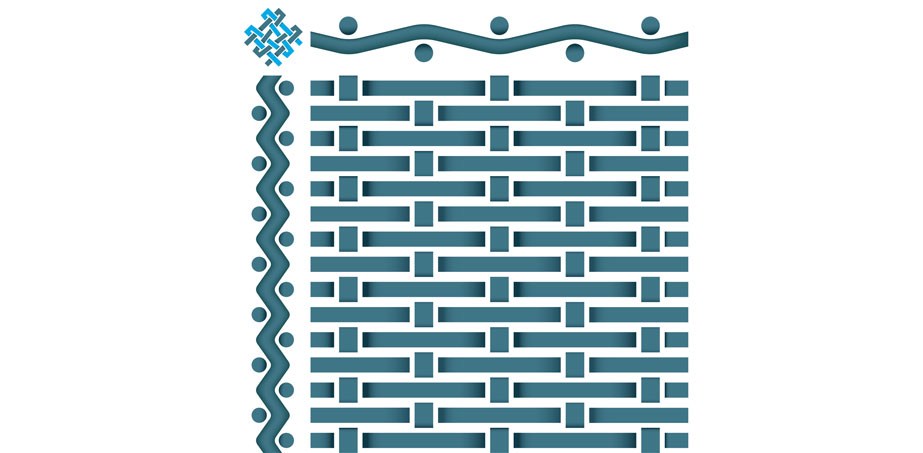

Dutch plain weave

A weaving pattern where the weft of the cloth has a smaller wire diameter than the warp wire. This way, the warp wires are closer to each other and there is barely an opening. This creates a much higher mechanical strength of the cloth than a plain weave for example. Dutch plain weave is used for industrial filtering where a high stiffness of the mesh is required.

The smallest opening with a Dutch plain weave we are able to supply is 45μm.

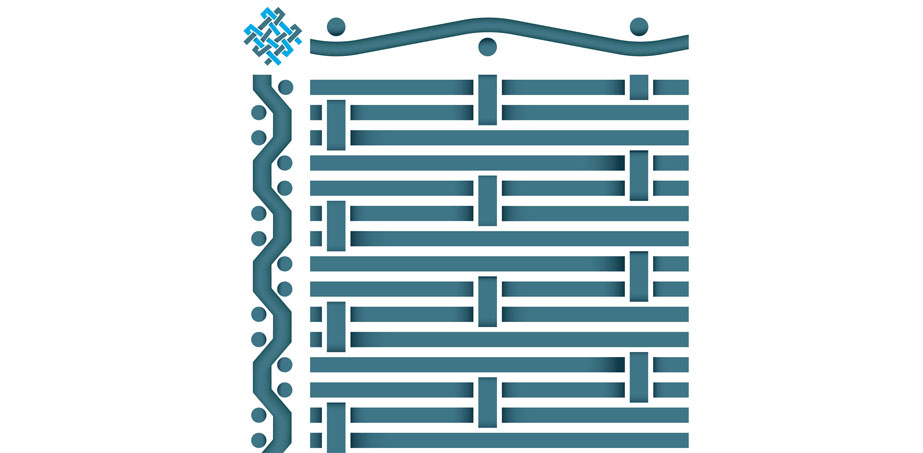

Dutch twilled weave

With this weaving pattern, a combination of twilled weave and Dutch plain weave is used. The weft wire has a smaller diameter than the warp wire. Furthermore, the warp wires are closer together. The wires are, similar to twilled weave, not woven per one, but per two wires. This gives the mesh strength in relation to its fineness. Because of these properties, this mesh is mainly used for heavy filtration.

The smallest available opening for a Dutch twilled weave we are able to supply is 5μm.

Specials

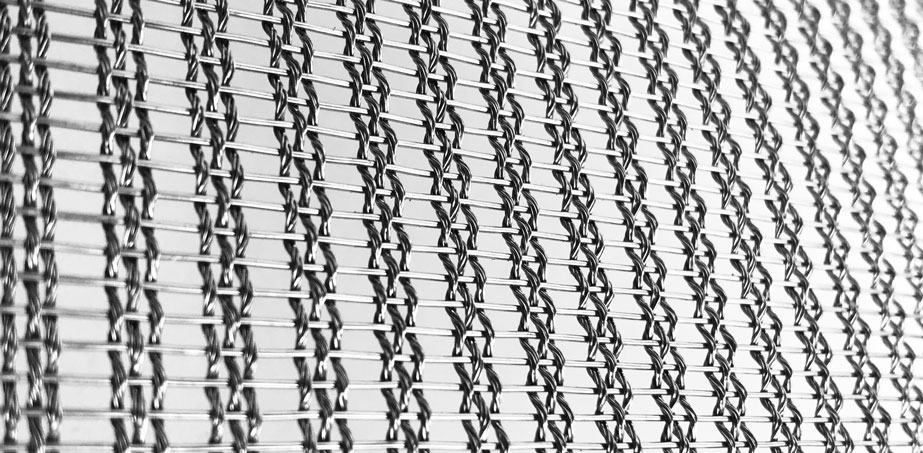

Besides the above-mentioned weaving patterns, there is an immense number of possibilities available. A few examples are weavings with flat wire combined with round wire or a twisted wire combined with a standard wire.

These kinds of mesh are used for architectural purposes on a regular basis.