Sintered mesh

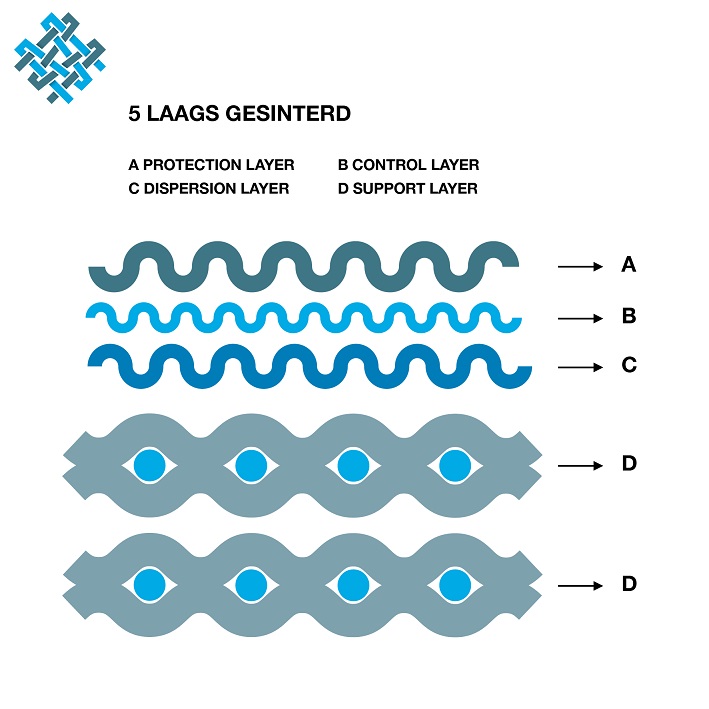

By sintering mesh, we can combine several types of mesh and create completely different characteristics. Properties which are important for an application can be thickness, permeability or a specific mechanical strength. By sintering mesh, these characteristics can be affected.

When mesh is sintered, it needs to undergo several processes. Before mesh can be sintered, it first needs to be flattened. This is done by calendaring. By calendaring the mesh, the wires are better connected to each other. After this, the calendared mesh is fixated in a furnace at high temperature. By adding an inert gas into the furnace the mesh will be sintered once it reaches the correct temperature.

Once the material is removed from the furnace, the sintered mesh will be cooled at a controlled temperature and multiple layers will be connected to each other.

Now the mesh has a rigid structure, is much more resistant against tearing and has a much higher mechanical strength.

Sintered material is used in gas filtration, air filtration, dust filtration or liquid filtration. Furthermore, sintered material can be seen in the (petro)chemical industry, water treatment and pharmaceutical industry.

Sintered mesh

Sintered mesh is mostly produced using stainless steel, Aisi 304, 316(L) and is available with a permeability of 1 to 100 micron.

Plates are available in standard dimensions of 500×1.000mm. and 600×1.200mm. If larger dimensions are required, plates can be connected to each other by welding.

Besides sintering solely mesh, we can also combine a mesh with perforated plate. In this case, the function of the perforated plate is a supportive one.

The mesh has much higher pressure resistance and a higher mechanical strength.

Sintered material is used in gas filtration, air filtration, dust filtration or liquid filtration. Furthermore, sintered material can be seen in the (petro)chemical industry, water treatment and pharmaceutical industry.

Mesh Masters supplies sintered material which exactly meets your requirements. This can be sintered plates, filter-rounds, or cylinders.